Real-time monitoring and control techniques for laser processing

Partners: LUT (Finland), AMSYS (Israel), ELAS (Lithuania)

The use of ultrafast lasers provides many new possibilities for microscale processing applications due to their ability for virtually thermal ablation and high peak power. One particularly useful application is a thin film laser scribing, which can be used for example in solar panel manufacturing in order to improve the efficiency of solar cells. Processing speed in laser scribing applications can reach as high as several meters per second, in combination with high quality requirements. Defects in the scribing line, resulting from disturbances in the process, will greatly affect the quality of the end product. Presently, there is a demand for research in the fields of process monitoring and quality control. LUT having huge experience in monitoring laser macro-processing processes is testing sensitivity and lateral resolution of the techniques to be applied with ultra-short pulse lasers, possessing not so much high average power but working at high pulse repetition rate.

On-line detection of defects during laser scribing: LUT developed the real-time monitoring system based on a highspeed camera and spectrometer. The monitoring tools include a spectrometer, a high-speed camera with an active Cavitar illumination system. With a high-speed camera (max 500 fps), recognition of the defects was achieved at the maximum process speed of 1100 mm/s. This was demonstrated for laser scribing in CIGS, Cr/Glass and Mo/PI.

Test bed for the on-line monitoring experiments and screen shot of the defect recognition software of LUT

Real-time online monitoring of laser scribing of CIGS solar cells using photodiodes: The goal was to develop and evaluate a method for monitoring the laser scribing process in real time using photodiodes to detect defects in the process. Set of photodetectors were tested with 20 W nanosecond fiber laser working at repetition rate up to 1 MHz. Sensitivity all the techniques was tested and limitations of the techniques were evaluated.

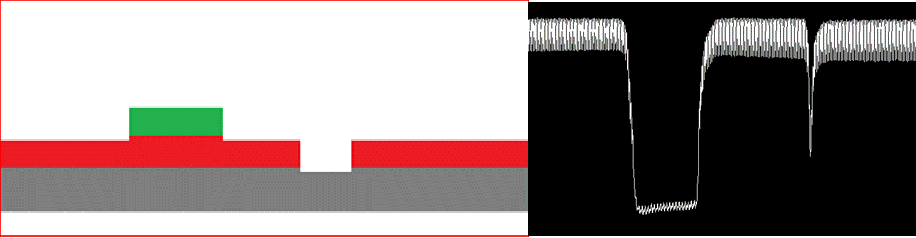

Diagram of test surface. Green: intact surface, red: second layer, grey: base layer and reflected light intensity curve when going over test scribed surface

Development of a real-time simulation platform based on industrial automation process of CIGS laser scribing: First real-time online simulator for CIGS manufacturing based on real-process has been developed. This automation system is developed based on the real-process in the industry. The necessity of developing such simulator was to have same process methodology for real-time monitoring. The simulator integrated with the real-time control system of the pulsed laser and the scanner head. Also, the developed monitoring systems which were developed in APPOLO project are integrated to the simulator. In this way, adaptive real-time control of the CIGS thin film scribing based on real industrial process came possible.

On-line monitoring of the laser process running at 50 m/s speed through polygon scanner (AMSYS): New on-line methods were designed and evaluated for the high-speed and precise in-line monitoring of laser scribing processes by utilising polygon scanners. The special optical system was developed to measure the reflection signal from the surface during the laser fabrication process. Such system helps to detect defects in the fabricated profile instantly and perform online monitoring of the laser process.

Microscope image of the P3 scribe made in the CIGS solar cell by direct laser ablation and the photodiode signal measured on-line during the ablation process

Online monitoring systems are crucial for any industrial process. Online defect detection system and on-line monitoring systems enables controlling laser microfabrication processes at high speeds and allows detection/correction of the defects. Such systems increase laser process feasibility and allow to minimise failures during microfabrication process in industrial systems.

Adoption of monitoring systems allows increasing laser technology feasibility and reliability in thin-film scribing for photovoltaics and electronics. It also reduces wasting of production material, increases scribing quality, as post scribing inspections are irrelevant when online monitors systems are used.